Rock Mechanics Laboratory

Arman Sanat Tadbir Andish Laboratory Complex consists of several sections, generally categorized into the Concrete and Building Materials Laboratory, Soil Mechanics and Geotechnical Laboratory, Materials and Metallurgy Laboratory, Asphalt Laboratory, Rock Mechanics Laboratory, and more. In this section, we introduce the Rock Mechanics Laboratory.

Rock Mechanics Laboratory Services of Arman Sanat Tadbir Andish

Construction and mining activities have dealt with rock since ancient times, and many infrastructure projects in the country—such as dam construction, road building, and open-pit and underground mining—are consistently faced with extensive rock operations. Determining the mechanical parameters of rock plays a key role in the proper design of these projects. Since field tests are not always easily feasible and involve high costs, laboratory tests remain the primary source for identifying rock properties.

Rock Index Tests

- Mass and Volume: For determining the mass of solid rock grains

- Moisture Content: Moisture content refers to the ratio of the weight of water present in the pores of a rock sample to the weight of the completely dried sample, expressed as a percentage.

- Density and Porosity: Porosity in rocks, defined as the ratio of the volume of void spaces between grains to the total volume, is an important factor in the mechanical and hydraulic behavior of the rock. Porosity arises due to various reasons, including formation conditions (primary porosity) and secondary processes such as weathering, metamorphism, mineral dissolution, recrystallization, and others (secondary porosity). In this test, porosity is quantitatively determined.

- Degree of Saturation :The ratio of the volume of water present in the rock to the total volume of void spaces represents the degree of saturation of the rock, which plays a significant role in determining the extent of water penetration into the structure.

- Bulk Density: Bulk density is usually measured in three states: total bulk density (γ), dry bulk density...dry(γ) and saturated bulk density (sat(γ), and saturated bulk density (γ). This parameter is one of the controlling factors of the pressure exerted on underground structures.

Uniaxial Compressive Strength Test and Ductility Determination:

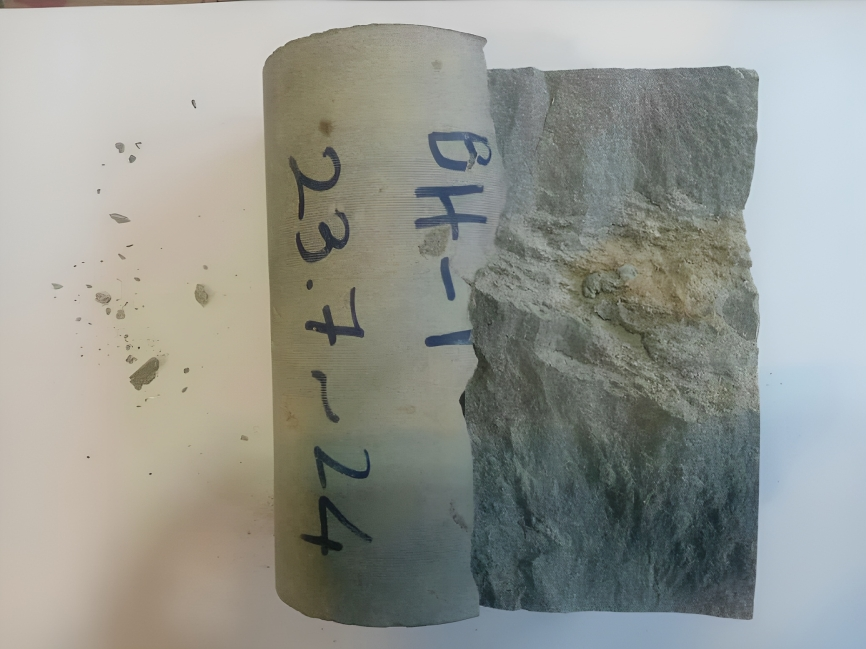

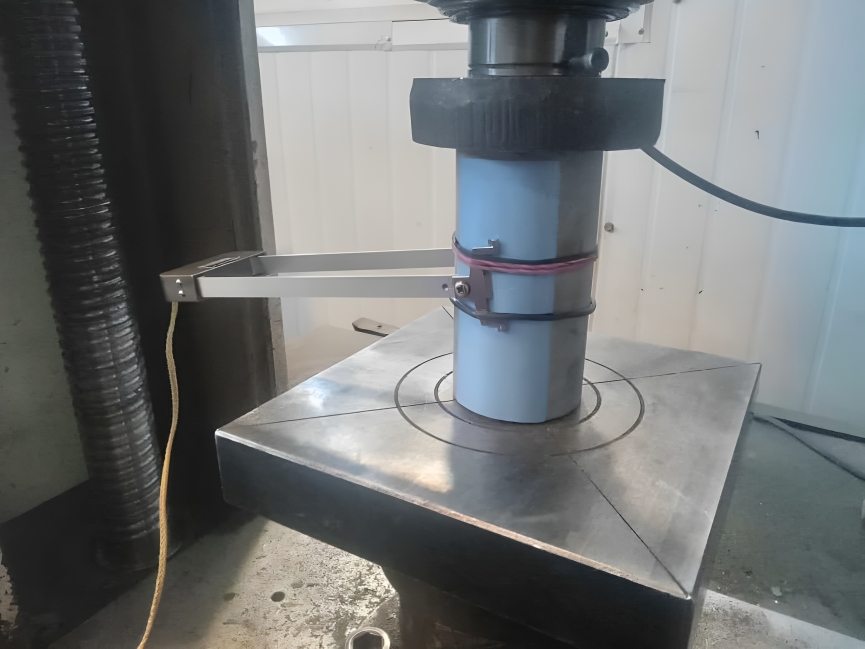

The uniaxial compressive strength test is the most common laboratory test for rock mechanics studies on intact rock samples. In this test, the rock sample is placed inside a frame and subjected to loading by a suitably rated hydraulic jack. To ensure uniform, non-point loading, a spherical bearing is used on the sample. The loading continues at a controlled rate until the rock fails.

Point Load Strength Test of Rock

This test is performed on rock cores in a diametral manner. The rock sample is fractured by applying a point load through a pair of conical jaws with spherical tips. At the moment of failure, the applied load is recorded by gauges, and then the point load index and the uniaxial compressive strength of the rock are determined. This device is portable and is a suitable tool for preliminary and field studies.

Triaxial Compressive Strength Test of Rock

This test is used to simulate the triaxial stress conditions that rocks experience deep underground. The simplest method to apply triaxial stress to a rock sample in the laboratory is by using a Hoek cell, which applies hydraulic lateral pressure while the sample is simultaneously subjected to axial stress. By performing this test under different lateral stress levels, the rock’s failure envelope is plotted, and based on it, the shear strength parameters—cohesion and internal friction angle—are determined.

Tensile Strength Test of Rock

Due to the difficulties in directly measuring the tensile strength of rock, the Brazilian test is commonly used for this purpose. In this test, disc-shaped samples are loaded diametrically between two jaws until a vertical tensile crack propagates and causes failure.

Shear Strength of Joints

To obtain the shear parameters of joints, the shear strength test of joints is used. In this test, the shear strength of a sample along a predetermined discontinuity or weak plane is measured. The rock sample is fixed in plaster or cement, then placed between two jaws (one fixed and one movable). While subjected to a normal force, a horizontal shear force is applied. During the test, the normal and shear forces, as well as the corresponding displacements, are measured.

Wave Velocity Test in Rock

Today, the use of dynamic methods to accurately and quickly estimate elastic constants in rock engineering is widely accepted. Since these tests are non-destructive, they have gained significant popularity.

The method involves sending elastic waves into the sample and measuring the velocity of the waves within it. The wave velocity depends on the compressive and tensile strength of the rock, or generally, the quality of the rock.

Schmidt Rebound Hardness Test (Schmidt Hammer)

This testing method is used to determine rock hardness using the Schmidt hammer, either in the field or in the laboratory.