Welding Inspection and Non-Destructive Testing

The Arman Sanat Tadbir Andish Laboratory Complex consists of various sections, generally categorized into the Concrete and Building Materials Laboratory, Soil Mechanics and Geotechnical Laboratory, Materials and Metallurgy Laboratory, Asphalt Laboratory, and others. In this section, we introduce the Technical Welding Inspection and Non-Destructive Testing (NDT) department.

Welding Inspection and Non-Destructive Testing (NDT) Services

Welding inspection and non-destructive testing (NDT) are two essential components in industries related to welding and metal fabrication. These tests are performed to ensure weld quality and to detect cracks, irregularities, and other defects in metal components.

Tank Testing – Ojan Shimi & Speedy Tabriz Factory

Industrial radiographic testing using X-ray and gamma rays (RT)

Industrial radiographic testing is one of the non-destructive testing (NDT) methods that uses X-rays or gamma rays. This test is performed to detect internal defects in metal components such as cracks, improper welds, voids, and structural inconsistencies. The two types of radiation commonly used in radiographic testing are X-rays and gamma rays.

Radiographic Testing (RT) of Stainless Steel Tanks

Ultrasonic testing (UT)

Ultrasonic Testing (UT) is a non-destructive testing method that uses high-frequency sound waves to detect internal defects in metal components, particularly welds. In this method, ultrasonic waves are transmitted through the metal piece, and based on the reflection and refraction of these waves from flaws such as cracks, voids, cavities, and irregularities within the material, defects can be identified and evaluated.

The advantages of ultrasonic testing include high accuracy, the ability to detect small defects, effective performance on components with various shapes, and no requirement for direct contact with the test piece.

Magnetic Particle Testing (MT)

Magnetic Particle Testing (MT) is a non-destructive testing method used to detect surface and near-surface defects in metallic components by applying a magnetic field. This test is especially effective for identifying cracks, scratches, corrosion, pits, and other discontinuities in metal parts.

Advantages of Magnetic Particle Testing include fast execution, the ability to detect surface and near-surface defects, applicability to various parts and materials, and usability in different environments.

Magnetic Particle Testing of Steel Mill Rollers

Liquid penetrant testing (PT)

Liquid Penetrant Testing (PT) is one of the non-destructive testing (NDT) methods used to detect surface defects in metallic components that can be reclaimed or reused. This test is employed to identify scratches, cracks, pits, and other surface imperfections in components.

Advantages of Liquid Penetrant Testing (PT) include fast execution, the ability to detect surface and recoverable defects, applicability to parts with various shapes and surface conditions, and usability in different environments.

LPG Tank Inspection and Control

Visual welding inspection (VT)

Weld inspection is one of the essential and critical stages in the manufacturing and welding process of metal components. The main goal of this inspection is to ensure the quality of the weld, detect and trace various welding defects, and verify the safety of the components and their compliance with relevant standards and customer specifications.

Welding Inspections for the Soufiyan Cement Expansion Project

Paint and Sandblasting Inspection (Thickness Measurement, Paint Adhesion Test, and Psychrometer)

Paint and sandblasting inspection holds special importance in industrial processes. These inspections are carried out to ensure quality and compliance with relevant standards.

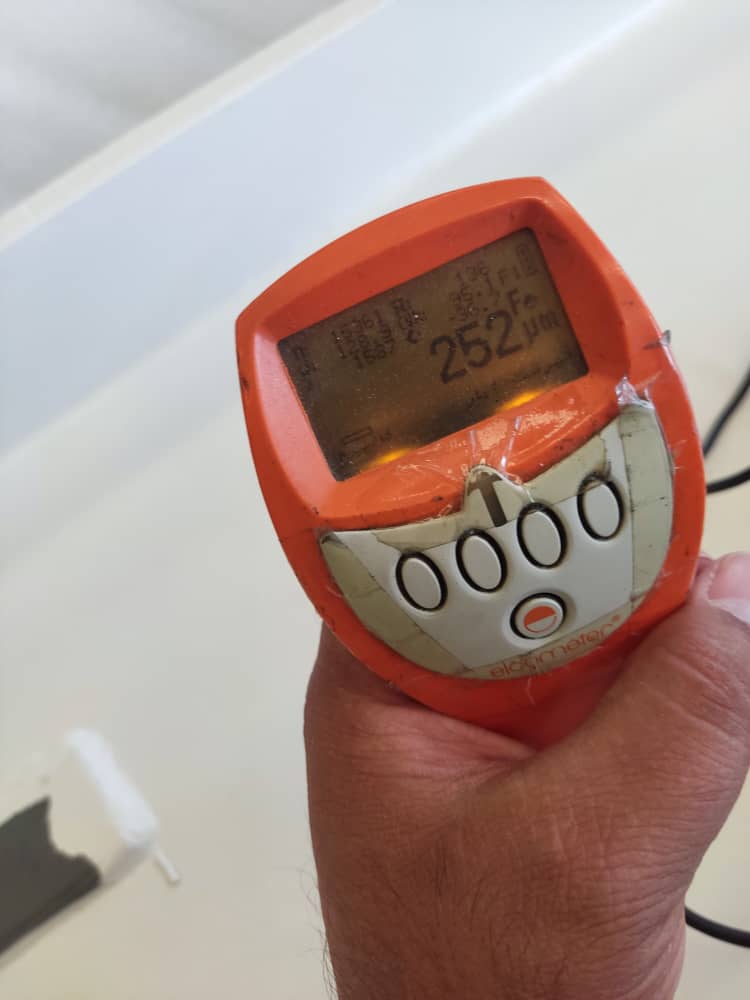

Coating Thickness Measurement of Components

Coating thickness measurement is an important non-destructive inspection method used to measure the thickness of paint or polymer coatings on various parts, especially metal components. Measuring the coating thickness helps determine the condition and service life of parts and verify compliance with standards and technical specifications. This method holds significant importance in various industries, including oil and gas, automotive, construction, aerospace, maritime, and more.

Kaolin fibers of Aras

Consulting, Quality Control, and Welding Services

Consulting, quality control, and welding services are provided across various industries to ensure quality, safety, and compliance with standards and technical specifications. These services are carried out by skilled and experienced teams who accurately identify issues and defects and offer appropriate solutions.

Phase 3 of Miyaneh Steel Complex

Preparation of Quality Control Plan and Inspection Test Plan (QC Plan & ITP)

The Quality Control Plan (QCP) and the Inspection and Test Plan (ITP) are essential tools in industrial processes, used to ensure the quality of a specific product or project. These documents define how the quality of work or the product should be maintained throughout the production or project execution phases, and how various inspection and testing methods are applied to verify quality compliance.

Welding Procedure Specification (WPS)

Preparing a Welding Procedure Specification (WPS) is one of the critical steps in the manufacturing and fabrication processes of welded metal components. The main objective of the WPS is to ensure the quality, strength, and performance of welded joints.

Complete Quality Control of Space Frame Structure from Start to Finish

Approval of welding procedure qualification record (PQR)

The Procedure Qualification Record (PQR) is an official document that contains detailed and validated information about the Welding Procedure Specification. This document is usually prepared by welding specialists and materials engineers and plays a crucial role in ensuring the quality of welded joints.

Issuance of welding qualification certificate (WQT)

Welding Qualification Test (WQT) is an official document that certifies a welder has performed welding correctly and in accordance with relevant standards and technical specifications. This certificate demonstrates the welder's ability to carry out specific welding tasks and is officially recognized.

Preparation of painting specifications (PS)

Painting Specification (PS) is a comprehensive and detailed document that defines the methods, specifications, and standards related to painting of parts, equipment, or structures. This specification is used to ensure the correct and uniform execution of the painting process while adhering to quality and safety standards.

Preparation and compilation of the final booklet (FINAL BOOK)

The Final Book is an important document used in projects and various processes. This document contains information and records that demonstrate a project, product, or process has been fully completed and all necessary details have been gathered.